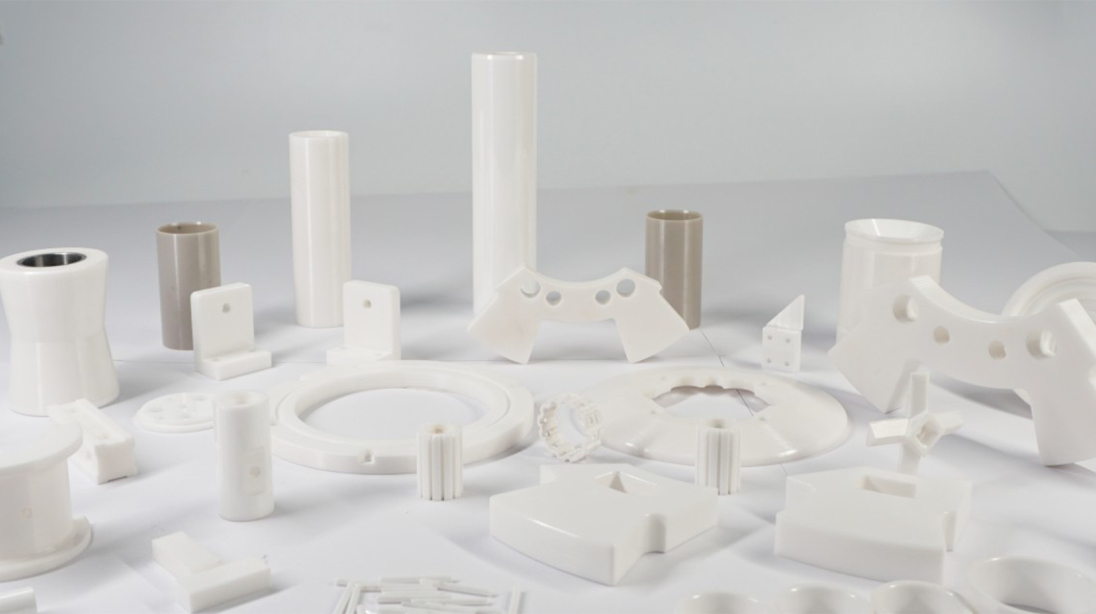

Shenzhen Compaq Industrial Ceramics Co., Ltd. was established in 2008 and is one of the largest modern precision ceramic companies in China. Through continuous research and development and strict production control, the company provides high-precision zirconia ceramic products for North America, Europe, Australia and other developing countries. Our products are widely used in more than ten electronic components, fixtures, zirconia ceramic structural parts, zirconia ceramic processing, chemical machinery industry accessories, medical industry accessories, flow valve body control accessories, tool parts, accessories, and daily necessities. industry sector.

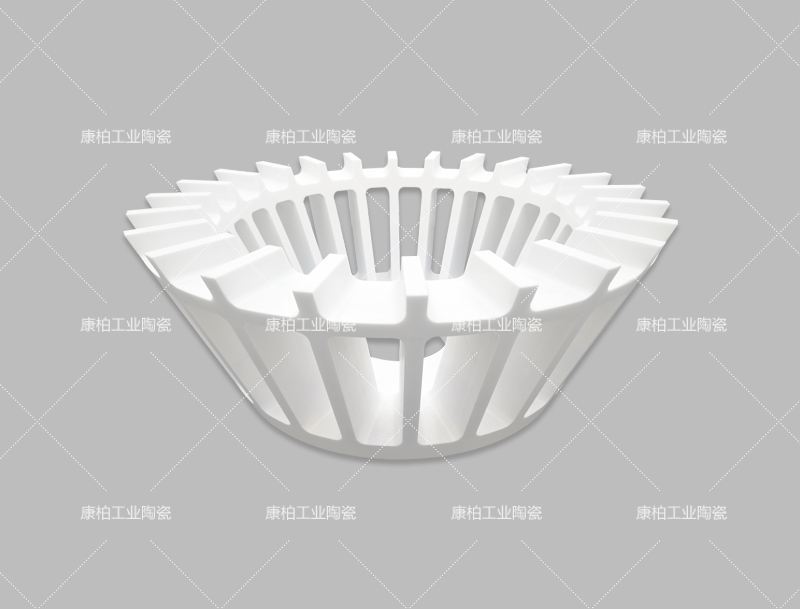

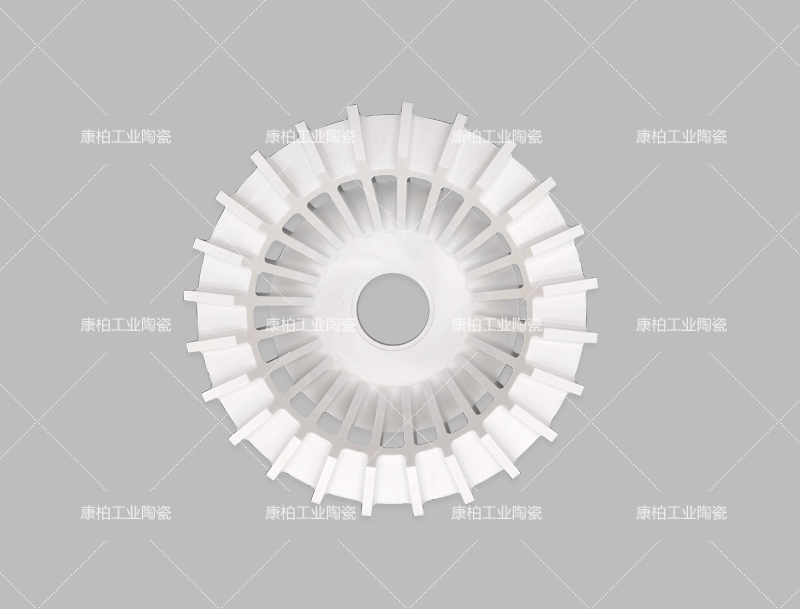

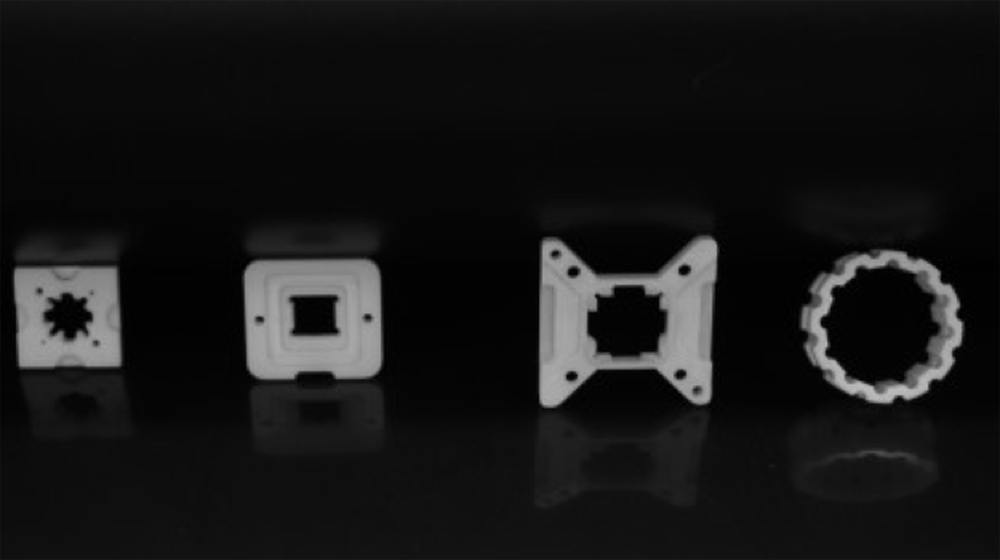

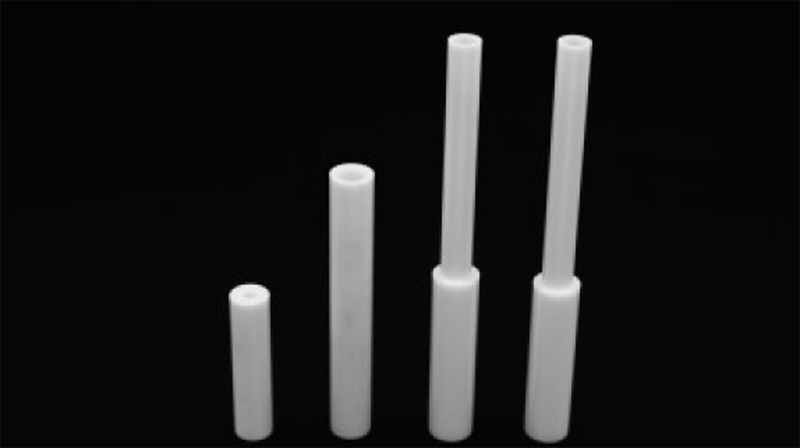

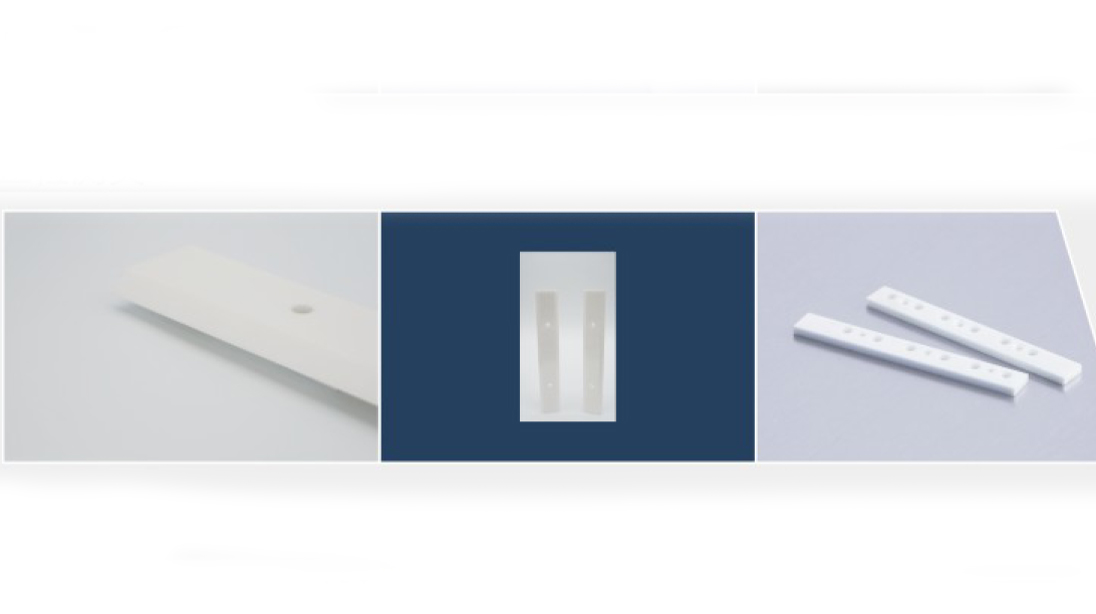

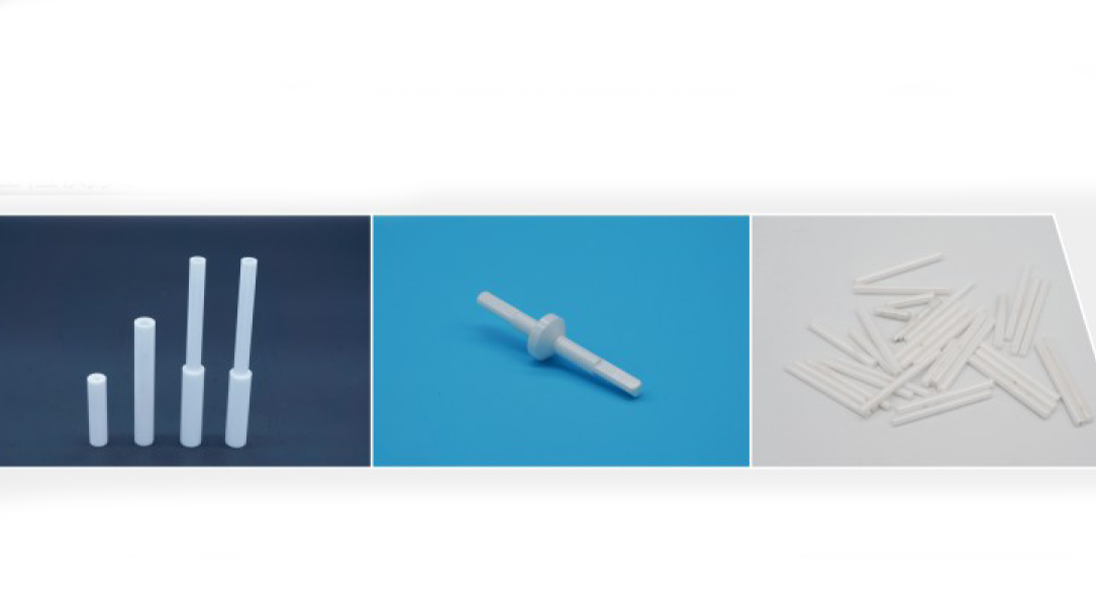

Compaq industrial zirconia ceramics manufacturer, the factory has a workshop of 10,000 square meters, with nearly 300 special ceramic production equipment, 1 tunnel kiln, 2 natural gas sintering lines, and 12 various electric furnaces. It can produce 100 tons of zirconia ceramic products per year. Products such as dry pressing and cold and injection products are exported to Europe, North America, Asia and other domestic and foreign markets, forming a one-stop design, research and development, mold making, blank molding, post-processing, etc. The production chain allows each ceramic product to be professionally and carefully polished from its birth to its forming, and it is outstanding.

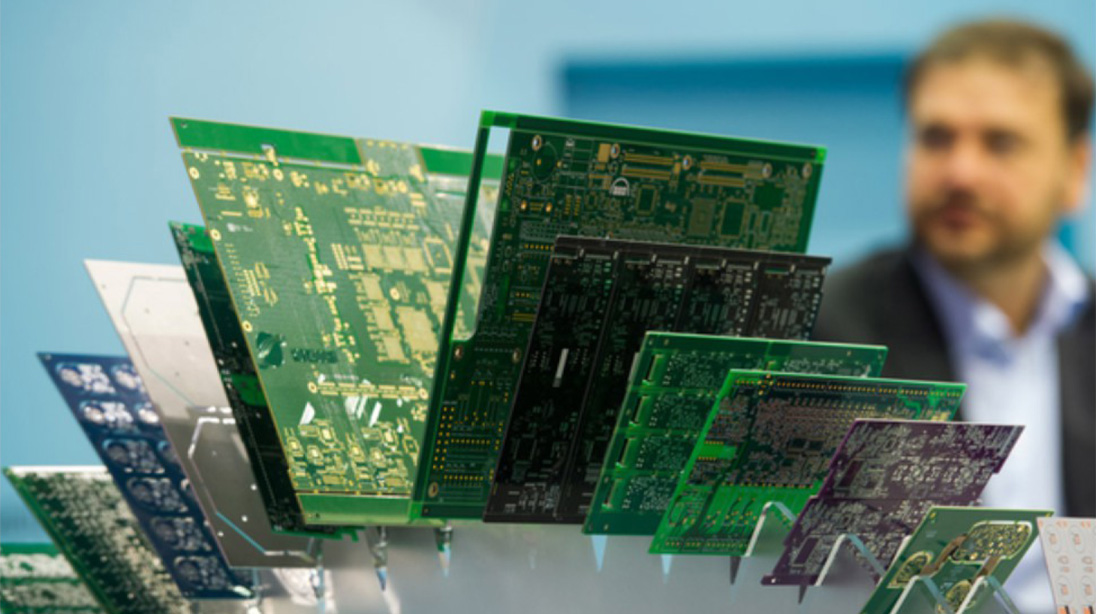

Zirconia ceramic is a ceramic material with zirconia (Al2O3) as the main body. It has good conductivity, mechanical strength and high temperature resistance when used for thick film integrated circuits.

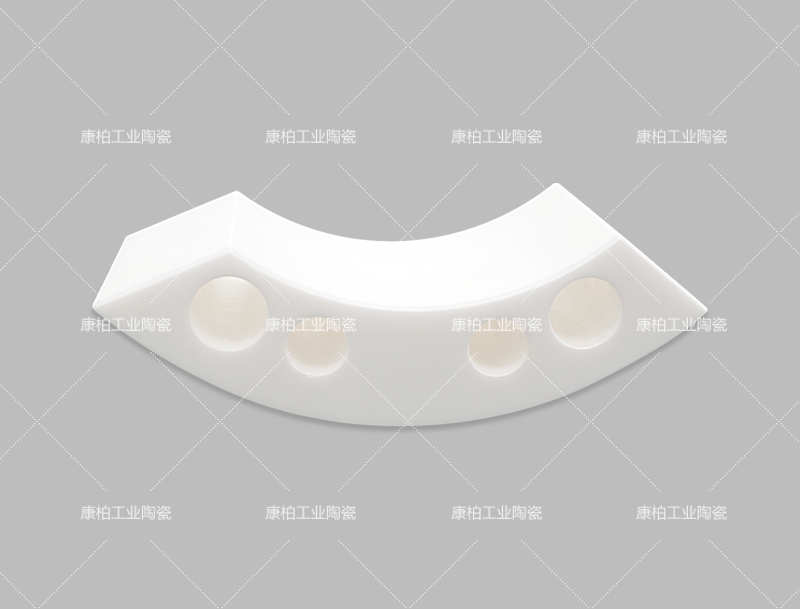

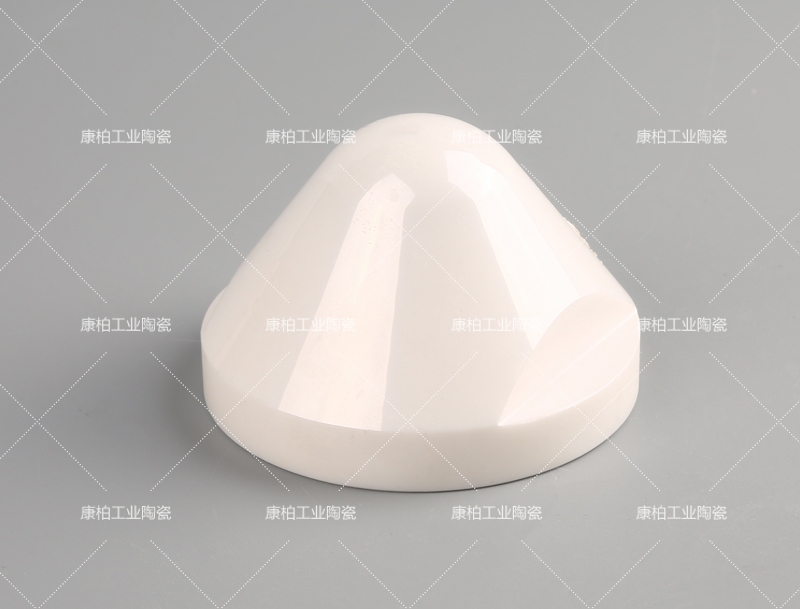

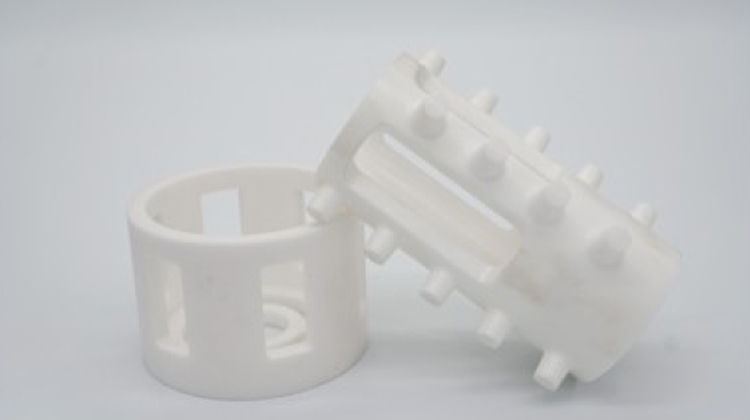

The wear resistance is equivalent to 266 times that of manganese steel and 171.5 times that of high-chromium cast iron. According to our customer follow-up survey over the past ten years, the service life of the equipment can be prolonged at least ten times under the same working conditions.

The density of zirconia ceramics is 6.03, which can greatly reduce the equipment load.

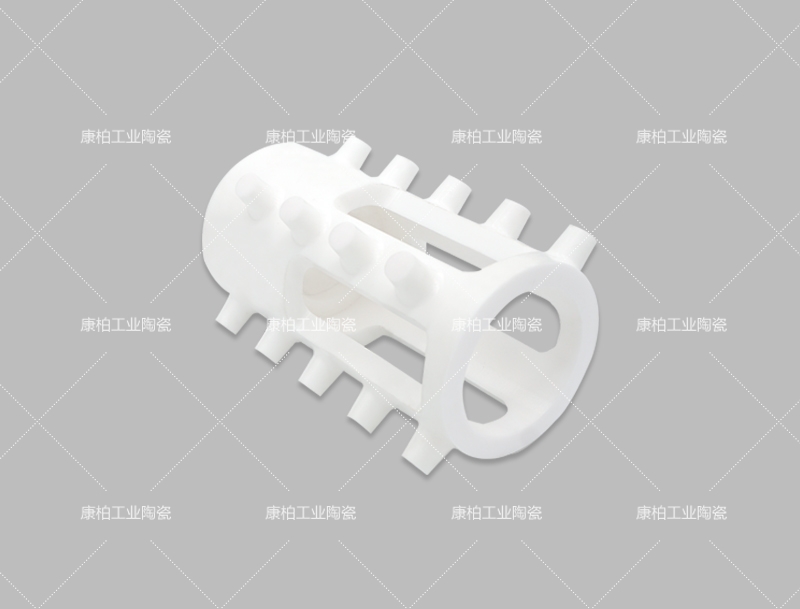

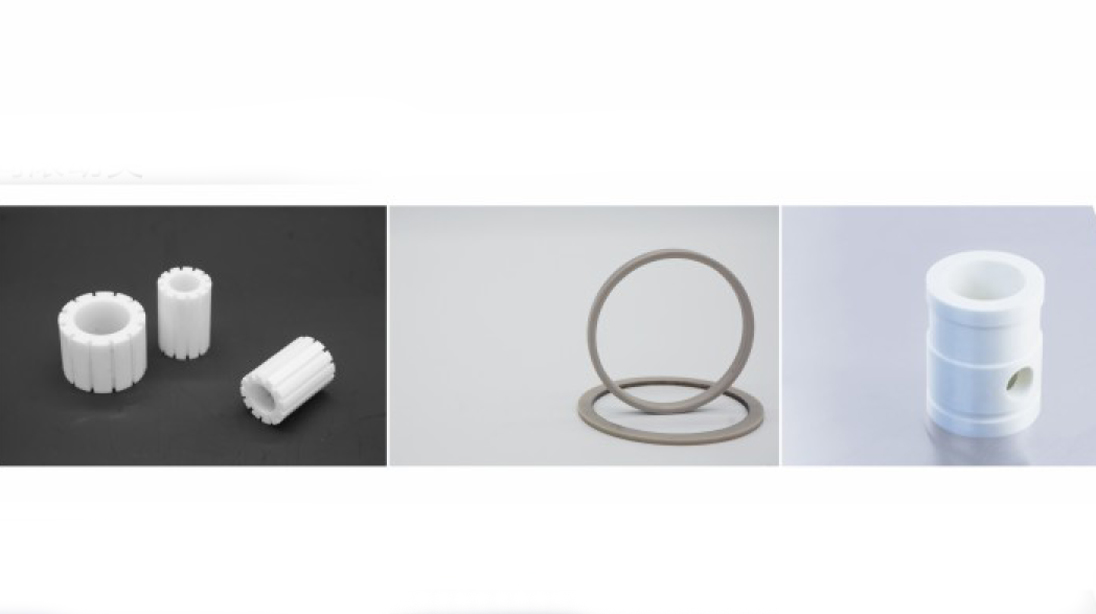

Zirconia ceramics are widely used ceramics. Because of their superior properties, they have become more and more widely used in modern society to meet the needs of daily use and special properties.

Good insulation performance – Zirconia is a good choice for packaging test of chips/chipsets.

Neutral physical and chemical property – Keeping contact-substance from pollution.

Good hardness / toughness and bending resistance – Can be used in many complex application scenarios.

Resistance to corrosion – Can be choosed as flow control value for acid / alkaline liquid.

Inorganic nonmetallic materials - Suitable for non-metallic operating environment.

The non-signal shielding of zirconia ceramics is resistant to falling, abrasion, and folding. At the...

2020-09-16 Read more→In the field of automotive coating, phosphating is the most common pre-treatment technology. After p...

2020-09-16 Read more→192023-12

From June 25-28, 2024, the 38th edtion of CERAMICS CHINA will be held at PWTC Expo (Poly World Trade Center Exhibition H...

162020-09

The non-signal shielding of zirconia ceramics is resistant to falling, abrasion, and folding. At the same time, the appe...

162020-09

In the field of automotive coating, phosphating is the most common pre-treatment technology. After phosphating the car b...

162020-09

There are many molding methods for alumina ceramics, such as extrusion, injection, dry pressing, hot pressing and other ...

Precision ceramics are new products that are different from traditional ceramics, also known as high...

2020-09-16 Read more→With the continuous development of China\'s real estate economy, people\'s demand for ceramics has a...

2020-09-16 Read more→162020-09

In recent years, competition in the ceramics industry has become more and more fierce.

162020-09

Perhaps the hottest material in the field of mobile phones this year is zirconia ceramics. Why is zirconia ceramics so h...

162020-09

Various machines and equipment are often used in modern chemical steel and other occupations. These equipments play a ve...

162020-09

Precision ceramics are new products that are different from traditional ceramics, also known as high-functional ceramics...